For heavy-duty testing

The well-established TPS technique – today used in more than 1000 laboratories – is highly appreciated for its ability to simultaneously and quickly determine thermal conductivity, thermal diffusivity and specific heat capacity from a single measurement, with minimum sample preparation. Utilizing the unique Hot Disk® sensors, the TPS 1500 system serves as a robust tool for testing the thermal properties of solids, powders, pastes and foams. If larger samples are available, also highly conducting samples, such as metals, semi-conductors and high-conductivity oxides, can be tested.

The TPS 1500 is designed as a reliable workhorse instrument for materials R&D within heavy-duty industries. The construction industry, for example, will see concrete and cement mixtures, woods, fibrous structures, and insulating materials readily and efficiently analysed. The Hot Disk Analysis software for the TPS 1500 system incorporates tools for automated measurements as well as automatic temperature control of external devices. In addition to the standard Isotropic and One-dimensional software modules the system can be extended with software to allow testing of anisotropic samples (Anisotropic module) and extremely light and low-conducting materials (Low-density/Highly-insulating module). Also available is a dedicated module for analysing specific heat capacity of solid samples, such as complex composites (Cp module).

The Hot Disk Thermal Analyser software for the TPS 1500 system incorporates tools for automated measurements as well as automatic temperature control of external devices. It also incorporates tools for exporting results to 3rd-party software (MS Excel), for additional processing or statistical analysis. For precise and automatic temperature readings an optional PT100 temperature sensor is available.

Key Features

Sensors: The TPS 1500 operates a selection of Hot Disk® sensors suitable for different materials and applications.

Temperature Control: Automatic Temperature series measurements (Isothermal Steps) are easy to perform using either an optional external Furnace or a temperature-controlled Bath Circulator. The Hot Disk Analysis software and TPS 1500 instrument controls the external device using RS-232 protocol.

Everything to get you started: The basic TPS 1500 setup includes everything you need to begin making measurements. The instrumentation includes: Software with standard isotropic module, one Sensor, Stainless Steel verification samples and a Room-Temperature Sample Holder.

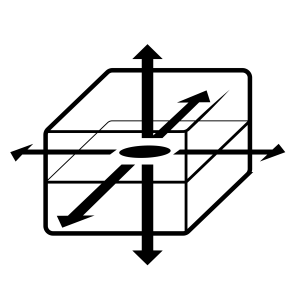

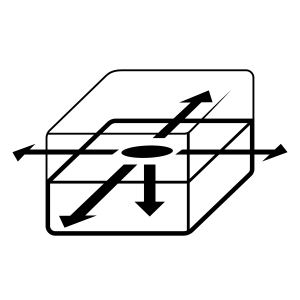

Optional Software Modules: In addition to the standard Isotropic and One-Dimensional modules, optional ones for Anisotropic, Specific Heat Capacity, and Low-Density, Highly-Insulating Samples are available.

TPS 1500 Specifications1

| Sample Types | Bulks, rods, laminates, composites, minerals, pellets, granules, beads, grains, powders, pastes, creams, gels, liquids, foams and insulators. |

|---|---|

| Evaluation | |

| Anisotropy | Yes, 2D anisotropic (uniaxial) materials can be characterised, using optional Anisotropic Measurement Module. |

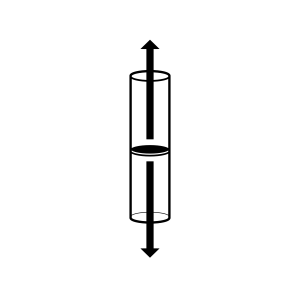

| One-Dimensional | Yes, axial estimations possible for a complex sample configuration. |

| Sample Dimensions | |

| Smallest | Bulk sample: 3 mm thick x 13 mm wide (circle or square). |

| Rod sample: 20 mm long x 7 mm wide (circle or square). | |

| Largest | Bulk sample: unlimited. |

| Rod sample: unlimited length x 60 mm wide (circle or square). | |

| Sample Temperature Range | -100°C to 750°C. |

| Core Instrument | RT. |

| With Optional TCU | Cryostat: -100°C to RT. |

| Low-to-High Temperature Chamber: -60°C to 300°C. | |

| Bath Circulator: -40°C to 200°C. | |

| Convection Oven: RT to 600°C. | |

| Muffle Furnace: RT to 750°C. | |

| Tubular Furnace: RT to 750°C (gas purging for >400°C is recommended). | |

| Measurement Time2 | 20 to 5120 seconds (depending on sample material and sensor dimensions). |

| Measurement Range | |

| Thermal Conductivity | Bulk sample: 0.01 to 50 W/m/K. |

| Rod sample: 1 to 400 W/m/K. | |

| Thermal Diffusivity | Bulk sample: 0.01 to 30 mm²/s. |

| Rod sample: 1 to 100 mm²/s. | |

| Thermal Effusivity | 20 to 35000 W√s/m²/K. |

| Specific Heat Capacity | Up to 5 MJ/m³/K. |

| Measurement Accuracy | |

| Thermal Conductivity | Better than 5%. |

| Thermal Diffusivity | Better than 10%. |

| Measurement Reproducibility3 | |

| Thermal Conductivity | Typically better than 2%. |

| Thermal Diffusivity | Typically better than 5%. |

| Measurement Repeatability4 | |

| Thermal Conductivity | Typically 0.59% (Stainless Steel bulk sample, Kapton-insulated Hot Disk® sensor model 5501, and 22°C sample temperature). |

| Thermal Diffusivity | Typically 0.80% (Stainless Steel bulk sample, Kapton-insulated Hot Disk® sensor model 5501, and 22°C sample temperature). |

| Measurement Sensitivity5 | |

| Temperature | Typically 44 μK (Stainless Steel sample, Kapton-insulated Hot Disk® sensor model 5501, and 22°C sample temperature). |

| Meets ISO Standard 22007-2 | Yes. |

|---|---|

| Measurement Modules | |

| Included | Isotropic, Single-Sided Testing, and One-Dimensional. |

| Optional | Anisotropic, Low-Density/Highly Insulating, Specific Heat Capacity, and Automation. |

| Sensor Models | |

| Hot Disk® sensor – Kapton-insulated | Models 5465, 5501, 8563, 4922, and 5599. |

| Hot Disk® sensor – Teflon-insulated | Models 5465 and 5501. |

| Hot Disk® sensor – Mica-insulated | Models 5465, 5082, 4921, 4922, and 5599. |

| Hot Strip® sensor – Kapton-insulated | All models. |

| Hot Cell® sensor – Cell size <250 mm | All models. |

| Hot Cell® sensor – Cell size >250 mm | Please inquire. |

| Instrument Environment | |

| Operating | 15°C to 30°C |

| Storage | -20°C to 45°C |

| Instrument Line Power | |

| Supply Voltage | 100 – 240 VAC, 50 – 60 Hz. |

| Power Consumption | 45 W typical, 155 W maximum. |

| Instrument Warm-Up | 2 hours to rated measurement performance. |

| Instrument Input and Output | |

| Rear Panel | USB type B connector (female) for connectivity. |

| RS232 connector (male) for optional TCU. | |

| Front Panel | LEMO 8 pin connector (female) for Hot Disk®, Hot Strip® or Hot Cell® sensor. |

| LEMO 4 pin connector (female) for optional PT100 temperature sensor. | |

| LEMO 4 pin connector (female) for obsolete sensor. | |

| Instrument Dimensions | 280 mm high x 455 mm wide x 490 mm deep. |

| Instrument Weight | 26 kg. |

| Instrument CE Marking | Yes. |

- Hot Disk AB reserves the right to make changes without prior notice, whether due to misprints, improved hardware, or extended software capabilities.↩︎

- Time of transient temperature reading. An additional temperature settling time that depends on the sample material and TCU (if applied) is required to ensure isothermal condition before the reading.↩︎

- Comparing measurements performed by different instrument set-ups.↩︎

- Variation in consecutive measurements performed by a single instrument set-up. Note that this value depends on sample material, sensor model, and sample temperature.↩︎

- Standard deviation in fitting ∆Τ(τ)-function to the transient temperature reading. Note that this value depends on sample material, sensor model, sample temperature, and can vary considerably.↩︎

TPS 1500 Measurement Demonstration

| Sample | |

|---|---|

| Material | Stainless Steel, AISI 316/316L. |

| Type | Bulk. |

| Temperature | 23°C. |

| Measurement Parameters | |

| Measurement Module | Isotropic. |

| Sensor Model | Kapton-insulated Hot Disk® sensor 5501 (radius 6.4 mm). |

| Measurement Time | 20 s. |

| Heating Power | 800 mW. |

| Measurement Results | |

| Data Points | 11-100. |

| Thermal Conductivity | 13.63 W/m/K. |

| Thermal Diffusivity | 3.608 mm²/s. |

| Specific Heat Capacity | 3.777 MJ/m³/K. |

| Probing Depth | 12.0 mm. |

| Temperature Increase | 0.4248 K. |

| Standard Deviation in Fitting ∆Τ(τ) | 35 μK. |

Included with the TPS 1500 instrument

Basic Option:

- 3 x Measurement Modules: Isotropic, Single-Sided Testing, and One-Dimensional.

- 1 x Kapton-insulated Hot Disk® or Hot Strip® sensor: Model free of choice, with cable.

Regular Complete Option:

- 5 x Measurement Modules: Isotropic, Anisotropic, Single-Sided Testing, One-Dimensional, and Specific Heat Capacity.

- 5 x Kapton-insulated Hot Disk® or Hot Strip® sensors: Models free of choice, with cable.

Extended Complete Option:

- 6 x Measurement Modules: Isotropic, Anisotropic, Single-Sided Testing, Low-Density/Highly Insulating, One-Dimensional, and Specific Heat Capacity.

- 5 x Kapton-insulated Hot Disk® or Hot Strip® sensors: Models free of choice, with cable.

Always included:

- Hot Disk® Desktop App software (latest version)

- 1 x Single-sided background insulation (single-sided testing).

- 1 x Room temperature sample holder (protective hood included).

- Instructions manual.

- Instrument test protocol.

- Power supply cord and USB cable.